This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Selha Group has acquired new means to strenghten and harmonize its machines park. The goal? To reinforce our process performances and to improve our flexibility.

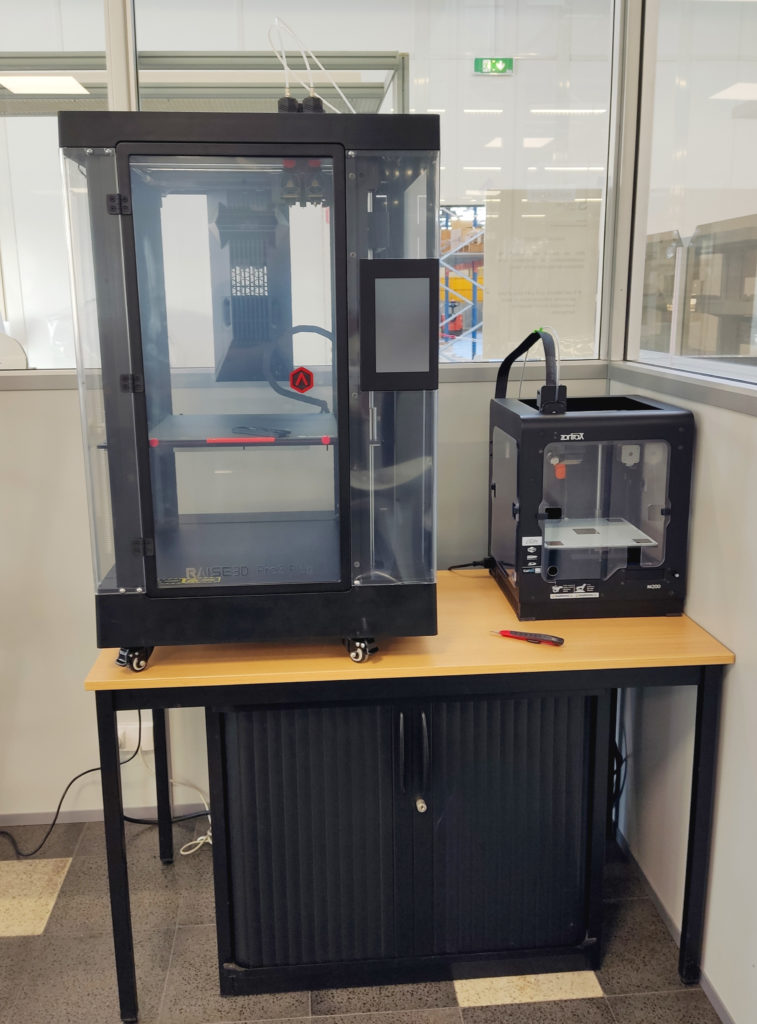

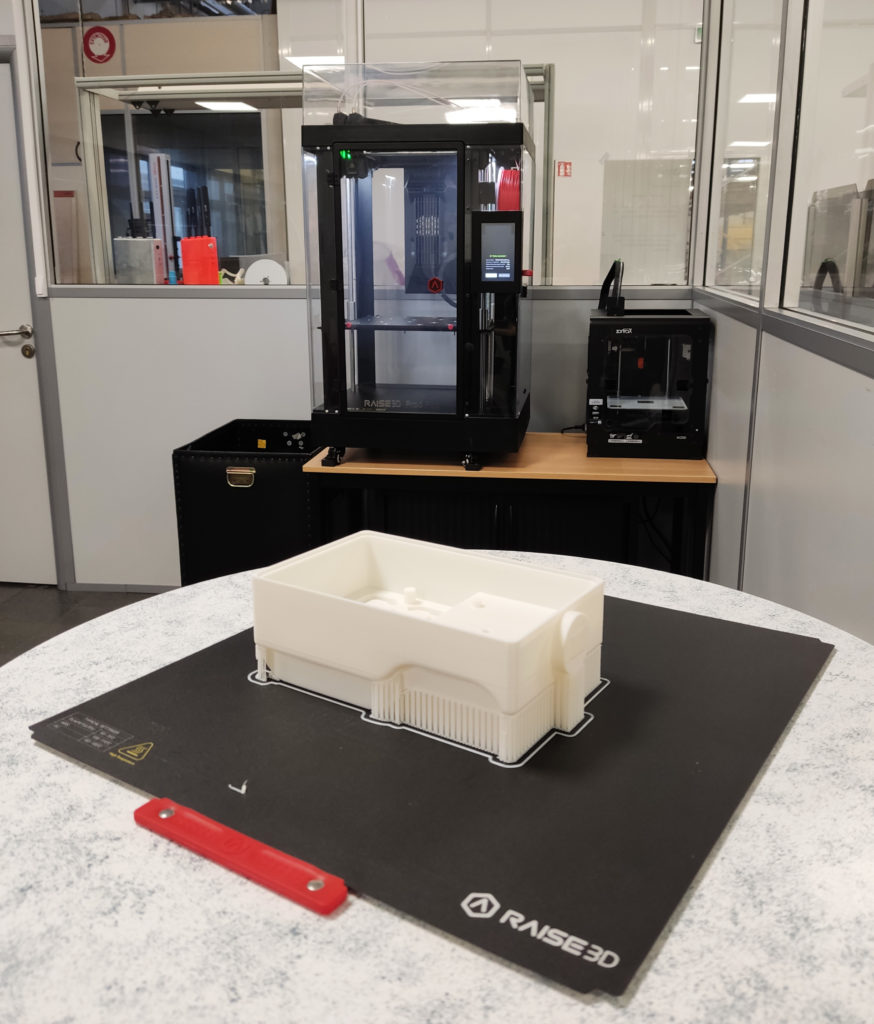

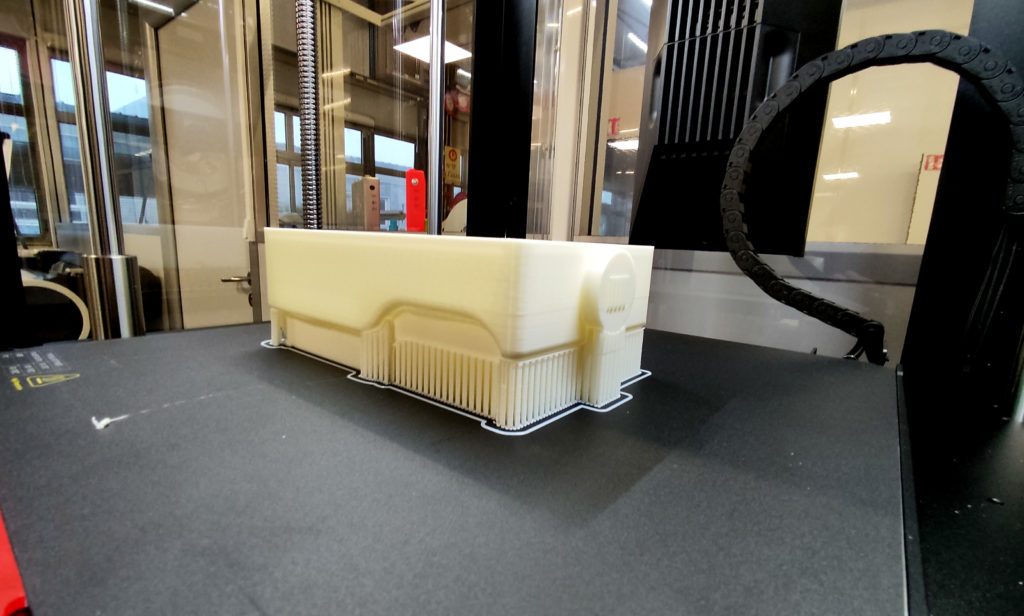

A new 3D printing press in our mechanical workshop

During a product development, numerous iterations are required to be able to project the future equipment. With this new 3D printing press, we are able to manufacture prototypes for our partners even quicker than before and therefore, save them some time in the development process of their products.

There are many advantages:

⏱️ a shortened production process,

💰 lower costs,

🎯 increased accuracy,

🚀 greater flexibility,

♻️ wastes avoided.

A new wave soldering in Normandy

A wave soldering with and without lead (Ersa Versa Flow 3/45) has been settled too in our Normandy’s plant. This new machine, best suited for our products requirements will be offer us more responsiveness, reactivity, a better repeatability and a significant time saving.

This investment was supported by the French relaunch plan.