This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

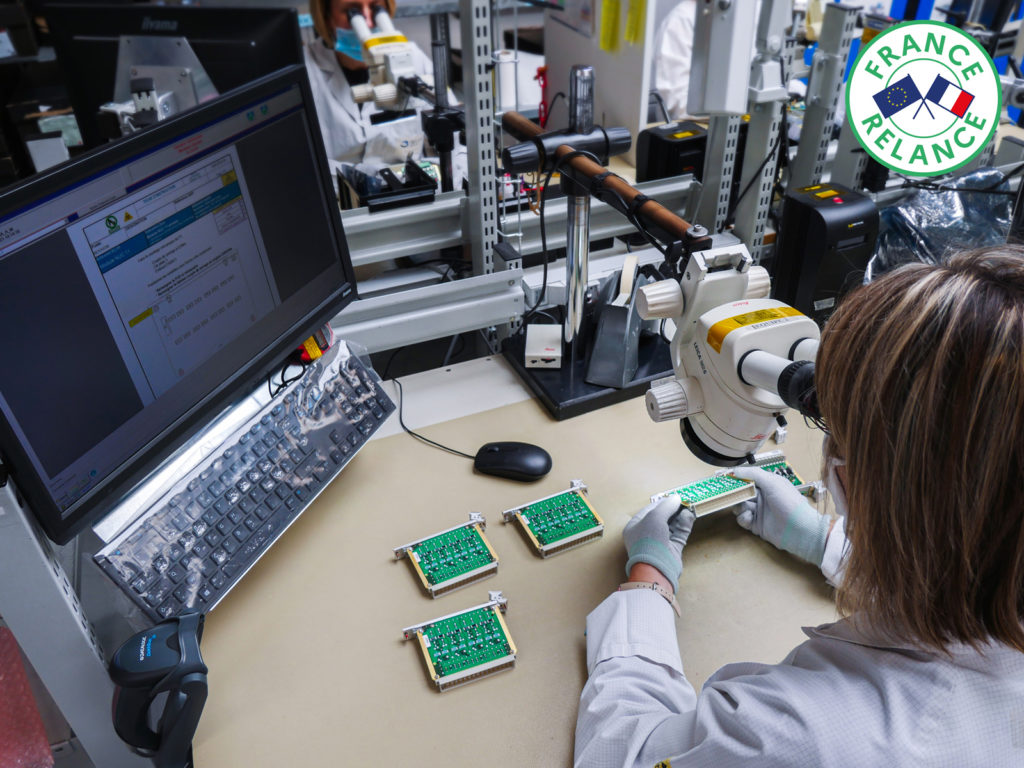

Fully aware that performance and competitiveness go together with flexibility and adaptability, our digitalization & modernization projects for our Renazé’s plant have accelerated in particular with a France Relance grant obtained at the end of 2020. First part of this device called Selha 4.0 with the implementation of a MES (Manufacturing Execution System) made in Selha Group..

The MES of Selha Group

Through a collaborative work mobilizing our teams skills (fabrication, computing, software development…) the internal Selha Group MES was called Tracking. This a tool full developed internally thats inspires to be scalable, intuitive and a communications bridge between all manufacturing informations. The materialization of this platform has accelerated thanks to France Relande grant. The funding provided allowed us to develop this management & pilotage interface and also equip computationally the workstations. These technological and material bricks are essential to make our manufacturing tool more robust and therefore to guarantee performances of our working methods. Today, Renazé’s plant is equipped with 200 digitalized workstations on which Tracking is used as an interface between the operator and the essential data for manufacuring like the manufacturing and control file. Indeed, this data file is now entirely paperless. The operator can work with updated in real-time instructions and consequently relay the informations in the systems to update files.

Key advantages

Working with an interface like Tracking allows all the staff to have a single, intuitive and effective digital gateway. The fabrication datas are gathered on an single portal and interact together to get a precise sight (identification, location, progress status…) of manufacturing stages of our products. We save more time and increase efficiency, all activities are optimized and so many key advantages noticed by our teams.

- Synchronization & data security : informations updates in real time on the different tools

- Flexibility & adpatability : developpement and additions of new customized functionalities

- Traceability : identification & location facilitated

- Productivity improvment : a single tool for simplifying data researchs, additions and manipulations

- Responsible resource consumption : a paperless environment

Next steps

Several key milestones in the internal development of this tool have been made with succes, by making Tracking operational in the fabrication plant. New implementations are already scheduled to make Tracking more exhaustive in few months. This tailor-made solution allows us to continually adapt our tool to our needs, preserving this flexibility, essential to our activities. It should be noted that few other modernization lines, from Selha 4.0 project, are currently being deployed…To discover very soon…