This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Increase your competitiveness!

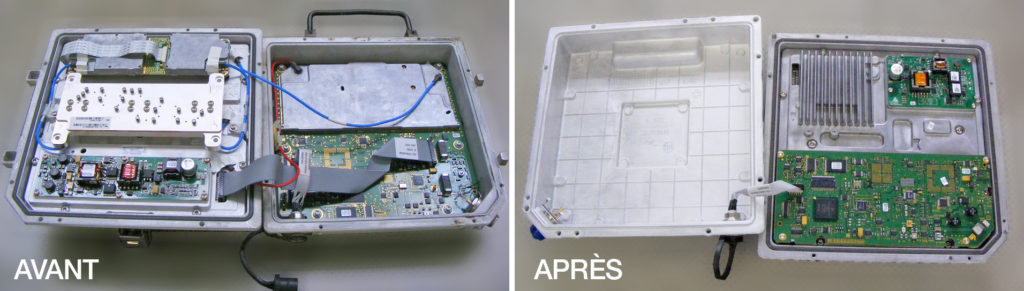

Thanks to our solutions EASYNDUS, the DFMA ( Design For Manufacture & Assembly) allows since the design stage to develop an optimized product for industrial manufacturing. Discover how we assisted one of our customers ! 👇

01THE CHALLENGE

85% of a product manufacturing costs are defined since the first step of design. Think the product manufacturing sine the design stage appears as an real stake to raise profitability and gain competitiveness in increasingly competitive markets. It is in that context that one of our customer, a telecom supplier asked us to detect opportunities for improving the re-design phase product. The challenge : save time and reduce production costs.

SOLUTION

To address this challenge, we have made an analysis both on the product it self and on the process using a standardised DFMA methodology. We have examined all elements constituting the bill of material and decomposed the product design and production and assembly stages too. From detailed description of each element and stage, we realized an analysis allowing us to distinguish added-value and necessary operations and not necessary ones. Thanks to our experience and inventiveness, we proposed, then, upgrade solutions to optimize, streamline and simplify operations and design of the product without affecting the functioning. Among our solutions : design changes, replacement of screws in favour of a piece to clip, standardization of some pieces, implementation of poka yoke.

RESULTS

Réduction of assembly costs

65 % less operations without added-value

Production times divided by 3

Deletion of 60% of the BOM

Number of references divided by 2

At the end of DFMA analysis, the customer decided to trust us. He followed a large part of our recommendations and the results speak for themselves.

- The production time cycle has been divided by 3especially because 2/3 of welding and handling operations have been deleted ;

- The initial BOM was lightened by 60% and the number of references has been divided by 2 ;

- Also, the quality has been improved thanks to anticipation and control of industrial risks..

THE DFMA IN A NUTSHELL

Why ? Make the product more reliable, control the industrial risks, reduce costs and improve compétitivité.

How ? Simplifying the product, optimizing the BOM, deleting quality risks, making the production more reliable, reducing time development…

When ? During the design stage of a new product or during a re-design.